Everloy Brand-New Descaling Nozzle

DNG type

Achieving higher impact force with grid straightener.

Excellent balance of filtering and clog-resistance with Multi-hole filter.

EVERLOY contributes to a sustainable society with developing high-quality products.

Features

Multi-hole filter

By adopting new-filter design with enlarged opening, excellent balance of filtering and clog-resistance is achieved.

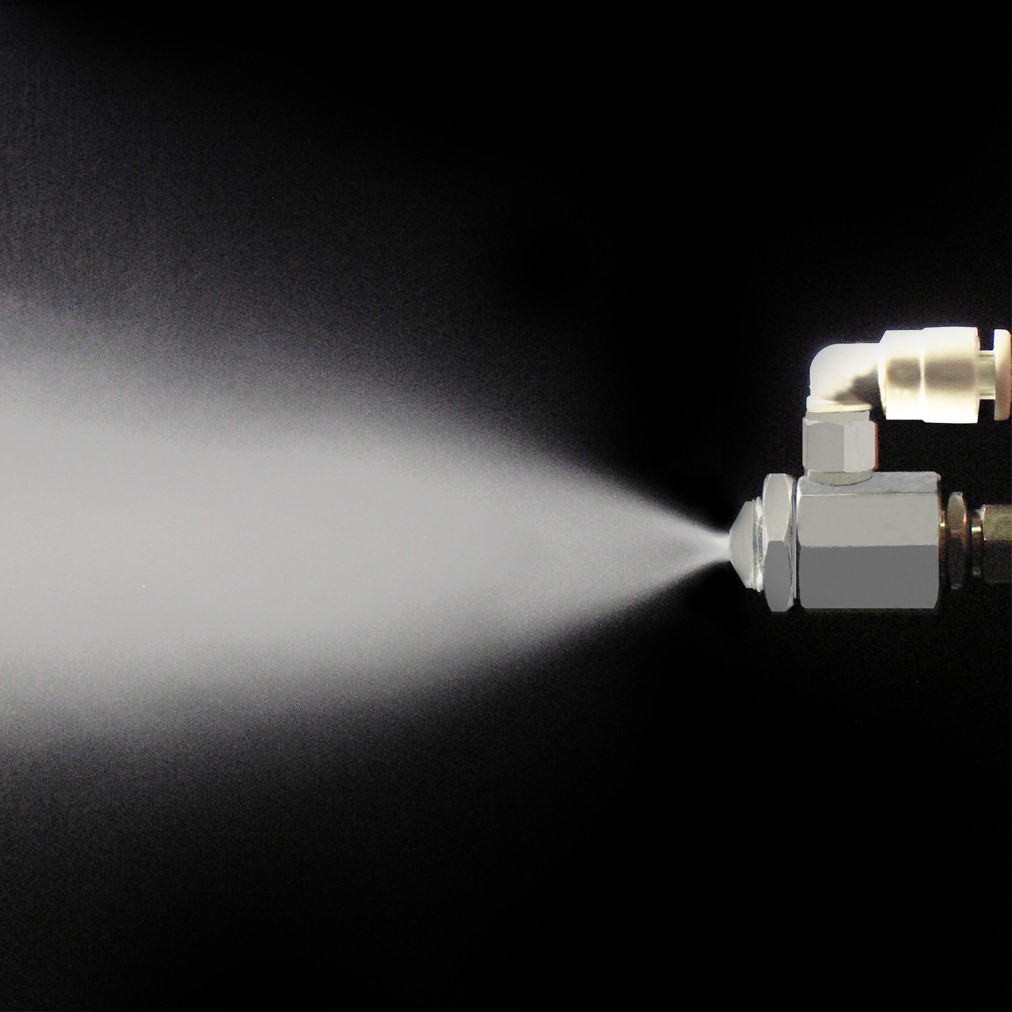

Grid straightener

Original designed grid straightener, based on new straightener concept for descaling nozzle, creates unprecedented high impact force.

100% stainless steel filter

100% stainless steel filter provides higher durability and longer nozzle life than conventional model.

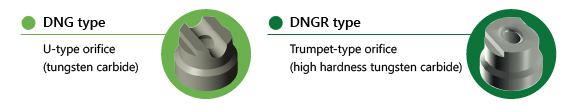

EVERLOY brand tungsten carbide tip

With our in-house manufactured carbide tips, we can provide your ideal spray angles and overlaps.

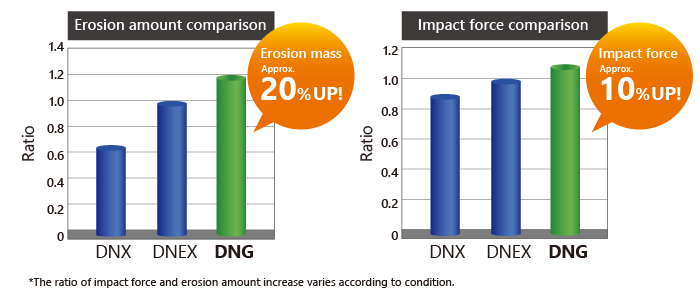

Performance

Carbide tip

Benefits of DNG Installation

DNG with the same flow rate as existing nozzles:

Improvement of scale removal efficiency due to higher descaling performance.

DNG with a lower flow rate than existing nozzles:

Reduction of fuel consumption for furnaces, pump power usage, and CO₂ emissions reduction.

Estimation of flow rate reduction effect

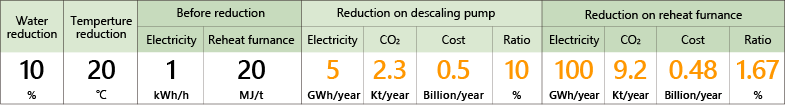

With assuming 10% reduction in the flow rate of the descaling nozzle

The estimated annual running cost saving:approx. JPY100 million (USD770,000-/EUR625,000-)

The estimated annual CO2 emission reduction:approx. 11,500 tons

* Please note that the flow rate reduction may vary depending on the specifications of the descaling nozzle.

Please consider carefully before implementation.

* The flow rate reduction effect is calculated based on the following assumptions and does not guarantee actual results.

Assumption

・Annual production amount: 5 million tons

・Flow rate reduction: 10%*

*Assuming that the water volume is reduced in proportion to the increase in impact force.

Estimated benefits

・ 10% reduction in water volume is assumed to result in a 20°C decrease in furnace temperature and a 1kWh/t reduction in power consumption.

・The energy required to heat steel is assumed to be 2 MJ/t・℃

・For the cost calculation, a reduction of 0.1 billion yen per 1 GWh and 0.48 billion yen per 100 TJ is assumed.

Catalog Download