Descaling is removing scale which is an oxidized layer on the surface of heated steels.

Flat fan pattern spray nozzles are commonly used for it,

Scale removal test

Water cooling is considered to play an important role in actual descaling.

Some scales were generated by heating a steel, and the scale removal performance was reported. The scale removal performance test was completed in different impact forces.

Also, the removed scale areas were compared after generating some scales and being removed on the steels in the same conditions.

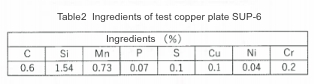

The test steel is a spring steel SUP-6(size: 100mm x 200mm x 8mm) polished by #800 with Si1.5% contained as shown in the chart 2.

Some scales were generated after heated up to 1100 degrees Celsius and left for 80 minutes. The steel was heated up by an electric furnace with maximum heating temperature 1150 degrees Celsius capability.

The descaling test was performed by moving the steel at 1.3m/s using an air cylinder.

The steel was store in an Ar gas atmosphere to cool down.

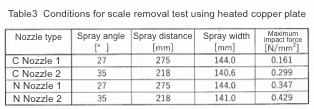

4 different kinds of nozzles were used for the test as the below chart 3 shows.

The spray distance varies, depending on spray angle in the same flow rate model,

to keep the same spray width. The purpose is to measure an influence of impact force without water cooling effect as much as possible.

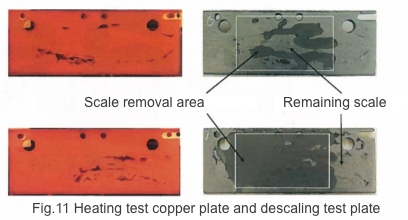

The picture 11 shows the steel plate before-and-after the test in 15MPa pressure and 300mm spray distance.

The percentage of scale removal on the steel plate after the test was filmed by a digital camera, and calculated by image processing the scale removed area.

The evaluation area is a white frame range on the steel plate after descaling. The white frame range is 80mm height excluding spray width 140mm and 10mm from top to bottom.

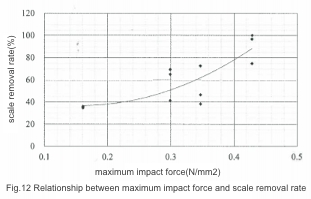

Picture 12 shows the test result.

The chart shows a stable scale removal at more than 0.4Nmm2 maximum impact force,

which is 90 precents of scale removal on average.

The data shows about 60 precents of scale removal result at less than 0.35Nmm2 maximum impact force including some variabilities.

Even a basic research on peeling behavior by direct spray descaling reports that scale removal perform deteriorated by decreasing pressure, and that none of scales was removed.

Based on this result, a certain imapct force is essential for descaling.