Basic knowledge and selection method of two-fluid spray nozzle

Everloy has been supplying a variety of two-fluid nozzles to all over the world.

You can learn both basic knowledges and selection methods in the two-fluid nozzle from the viewpoint of a spray nozzle expert.

Two-fluid nozzle

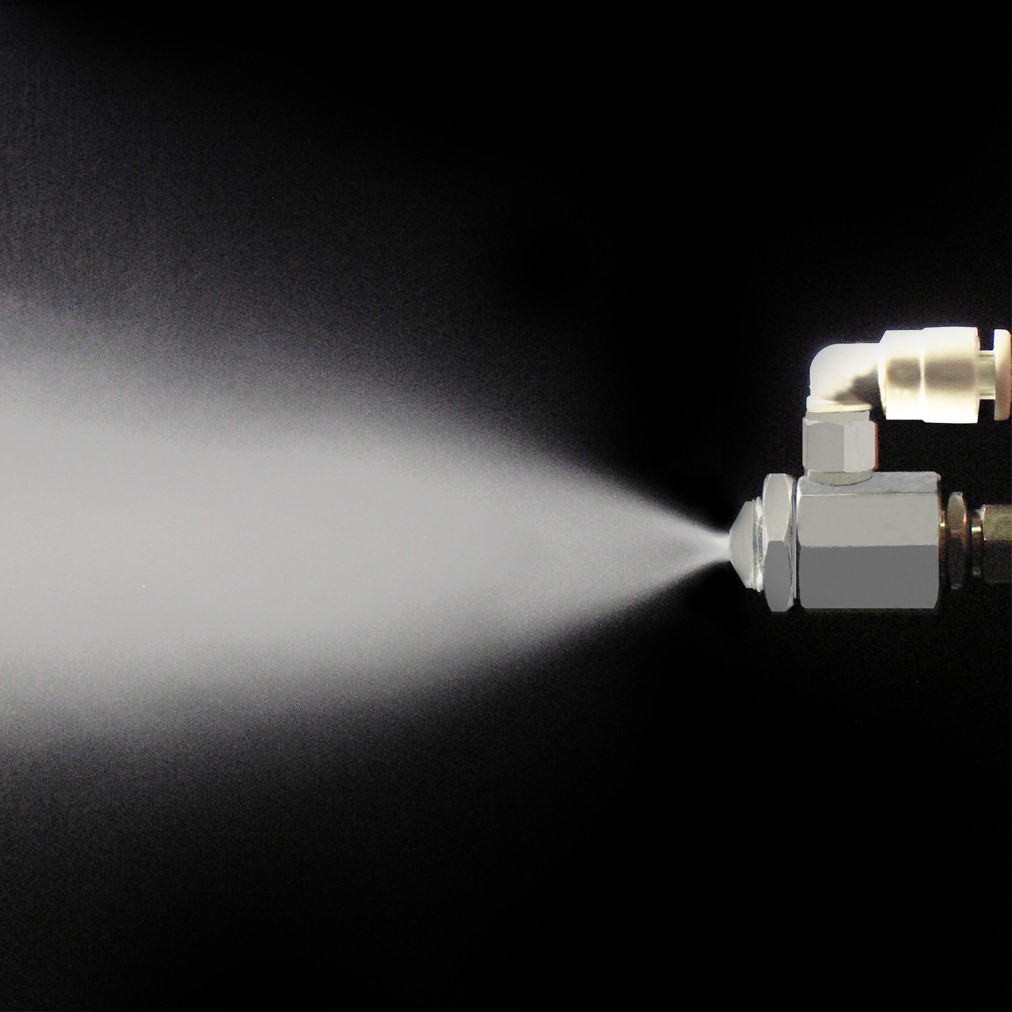

The two-fluid nozzle generally sprays both air and a liquid.

Compared with a hydraulic nozzle,

various spray patterns are formed by mixing some air and liquids in the two-fluid nozzle.

Note that nozzles are commonly used at less than 0.7MPa since the air is supplied by an air compressor.

Same as a hydraulic nozzle, nozzle selection is required for its purpose and application.

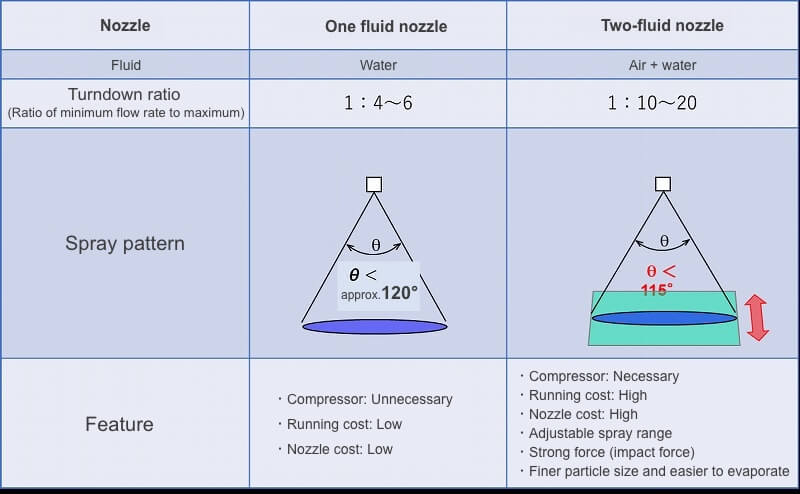

Comparison of hydraulic nozzle with two-fluid nozzle

*Turndown is a ratio from minimum flow rate to maximum.

Turndown is shown as 10 times in the minimum flow as 1L/min and the maximum one as 10L/mins.

The above chart shows a comparison of the hydraulic nozzle with a two-fluid.

Compared with the hydraulic nozzle, the two-fluid nozzle can provide such a big turndown in the specified flow rate range by mixing some air even though a wide spray angle is not formed.

The reason is that mixing some air even with a small amount of liquid makes the spray pattern and angel stable. Also, a strong impact force and a small particle are generated because of mixing some air, which is one of some specialties.

Running costs are higher since an air compressor is required to supply some air. Additionally, compared with a hydraulic nozzle, the two-fluid one's unit price costs more because of a complex structure.

References

Basic knowledge and selection method in hydraulic nozzle

Basic knowledge and selection method in two-fluid nozzle

Selection method of two-fluid spray nozzle

Equipment check

Check a equipment specification before selecting a two-fluid nozzle.

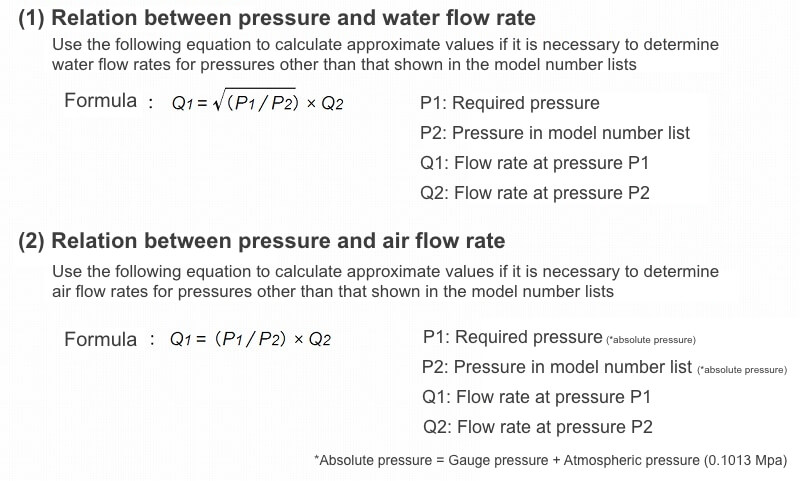

Pressure and flow rate to the spray nozzle all depend on a pump specification and piping.

Check a connecting part of a header such as threading since the two-fluid nozzle connecting part can be different.

Also, note that pipe flow velocity plays an important role.

Check the below link for more details.

References

Flow velocity and flow rate in each piping size

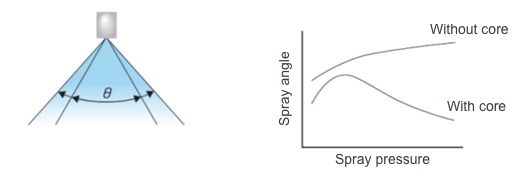

Note that the spray angel change may vary, depending on the nozzle specifications

when there are any flow rate ranges.

A spray angle in some nozzles with an insert core such as full-cone nozzle

increases up to certain pressure and decreases afterwards, which is different from the spray angle increase by pressure increase in general.

Check conditions

Check the condition in which the spray nozzle is used.

A material for the optimized two-fluid nozzle depends on a surrounding

temperature and a liquid characteristic.

There might be a clogging concern in case of any foreign materials included in the liquid.

If the foreign material size is informed, we will be able to propose a spray nozzle with the minimum flow passage considered.

Select a specification of the two-fluid nozzle

Select the pressure, flow rate, spray pattern and spray angle

in 1 piece of spray nozzle.

Note that, if any particle size is requested, the nozzle performance might not be sufficient ,depending on some conditions such as pressure and others.

In case multiple two-fluid nozzle are lined up in a row, contact us with the total flow rate and a width of sprayed object.

Selections of two-fluid nozzle and model

Referring our catalog, select a spray nozzle type based on the spray pattern such as flat, full-cone, curtain and others.

After selecting the two-fluid nozzle, check the flow rate and spray angle under the specified pressure.

Check the minimum flow passage on our catalog if necessary.

You can select the nozzle model by following the above processes.

Contact us for the further information

We have a variety of two-fluid spray nozzles available on our website, starting typical two-fluid nozzle air mist nozzle.

A few milli to hundred litters per minute flow rate can be applicable.

To meet your requests, our customizations are also available.

Relevant information

Learn more about two-fluid nozzle types