Challenges

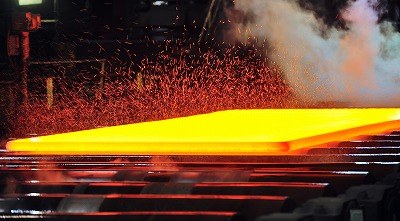

In hot strip mills and plate mills, descaling nozzles are utilized to remove scale from the steel surface. If scale is not properly removed, the scale, which is harder than the steel itself, can bite into the rolled coils, causing surface defects known as scale marks on the steel plate and resulting in quality issues.

Hot rolling mills are large equipment that use approximately 300-500 descaling nozzles throughout the entire facility. This results in high water consumption and increased power consumption for pumps, leading to higher running costs. In this case, our customer was considering changing their nozzles to reduce water consumption and lower running costs.

Solution

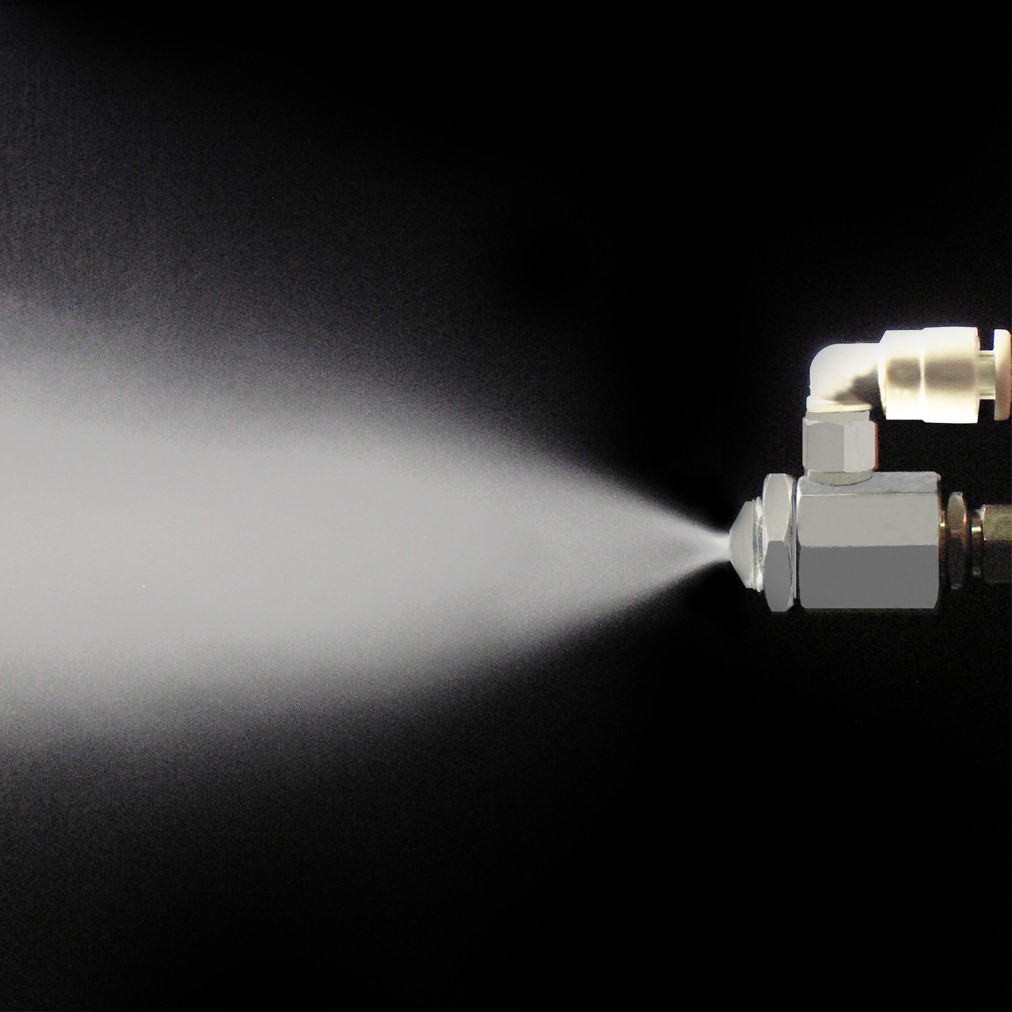

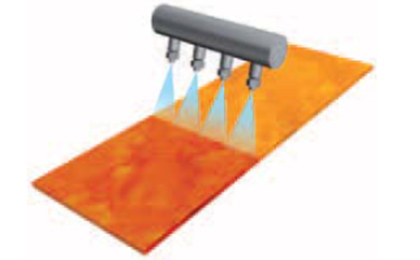

Since the descaling nozzles mounted on the hot rolling mill were standard types, we proposed high-impact descaling nozzles from our product lineup. The high-impact descaling nozzles can improve maximum impact force, which is an indicator of descaling performance, by 10%-20% compared to conventional types. With this performance improvement, water volume can be reduced while maintaining the same level of performance as before. Additionally, we proposed reviewing the nozzle spray angle and arrangement to further enhance impact force.

Trial

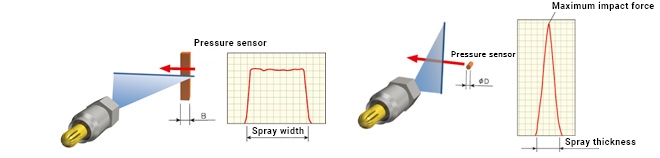

First, we conducted impact force distribution measurements using the conventional descaling nozzles with the same nozzle arrangement as the actual equipment. Then, we performed similar impact force measurements with the high-impact descaling nozzles with reduced water volume and compared the maximum impact forces.

While we confirmed that water volume could be reduced, to achieve even greater water reduction, we produced prototype nozzles with optimized spray angles and optimized nozzle arrangements, creating nozzles that could maximize water reduction while maintaining descaling performance.