You can learn what mist nozzle is from the viewpoint of a spray nozzle specialist.

Mist nozzle

Mist nozzle mixes some air and water, and sprays the atomized mixture. The internal structure is more complicated than hydraulic nozzle's, and high degree of accuracy is required in some mist nozzles.

Structure of mist nozzle

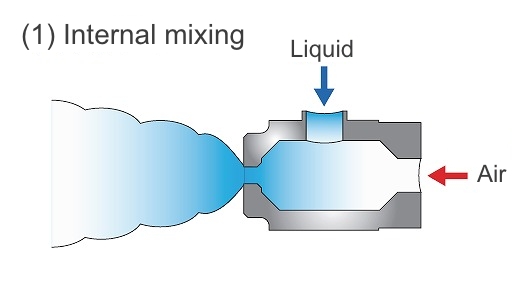

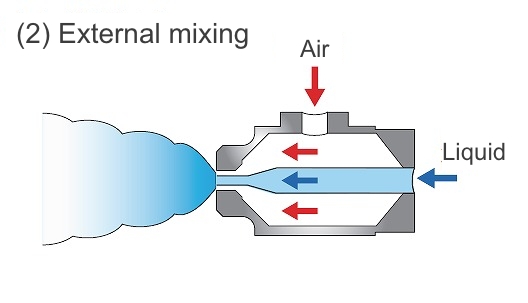

Mist nozzle is composed of internal mixing type and external mixing one. Both of them spray atomized mixture by mixing some air and water.

Internal mixing type

In an internal mixing type, some air and water are separately supplied, and they are internally mixed to be atomized. Simple air and water supply to inside the mist nozzle does not enable the mist nozzle to create stable atomized spray. In the internal mixing type nozzles such as an air mist nozzle, the internal mixing space structure is well devised for better atomization and designed to block the counterflow from the air supply inlet to the water.

External mixing type

In an external mixing nozzle, some air and water are mixed at the tip of the nozzle instead of inside the nozzle. The air and water are separately supplied like an internal mixing type. A major characteristic is that the water is automatically supplied only by air pressure without any air pressured force, which is called siphon. You could reduce some costs for pumps and booster pumps. Please note that the flow rate can change by a pressure head. Siphon is suitable for the nozzle with a small flow rate, not the one with a big flow amount since certain amount of air would be required to suck the huge amount of water.

Air mist nozzle application and example

Air mist nozzles are often used for chemical spray, painting, food spray process and humidification. The most important thing in introducing mist nozzle is uniform spray pattern. The followings are actual introducing examples.

Mist nozzle for fluidized bed dryer

A particle size in spraying is important in fluidized bed dryers since the materials of medicine and food are powered by spraying. The required particle size is different in each material. To meet the requirement, spray nozzles have to be adjusted. Here is an example of solving a customer side issue by installing particle size adjustment mechanism.

Related information

Learn more about an adjustment mechanism of particle size in the customized spray nozzles for fluidized bed dryers

Mist nozzle for continuous casting machine

In steel industry, to coagulate inside slabs, water cooling by spray nozzle is used for molten steel coagulation process in continuous casting machines. Coagulation by water spray is called the second cooling, which plays an important roll in casting production and has an huge impact on the casting quality. Here is an example of creating uniform cooling by making a customized nozzle.

Related information

Learn more about uniform cooling in the customized spray nozzles for continuous casting machine.

Mist nozzle for smoke exhaust desulfurization equipment

In lime and plaster method base smoke exhaust desulfurization equipment, lime slurry spray by spray nozzle is used in a process to remove SO2 from a smoke exhaust. The lime slurry is a mixed liquid with some water. Some wear of spray nozzle easily occurs by lime slurry spray, which deteriorate the spray nozzle performance. Specifically, the spray pattern changes due to the spray nozzle shape caused by the wear. Because of the shape change, the original nozzle performance is not shown.

Here is an example of solving a customer side issue by creating a cemented carbide base customized nozzle.

Related information

Here is an example of spray nozzle life time extension by changing cemented carbide customized nozzle

Contact us

We have a variety of mist spray nozzles available. To meet your requests, our customizations are also available. Contact us for any issues and concerns of spray nozzles.

Related information

Mist particle size in spray nozzle