Challenges

Components used in medical devices require precision cleaning at each manufacturing step, such as cutting and polishing. However, many parts are small or feature intricate geometries, making effective cleaning challenging. In this case, the customer used an automated cleaning system to remove metal shavings generated during the machining of pipe-shaped components.

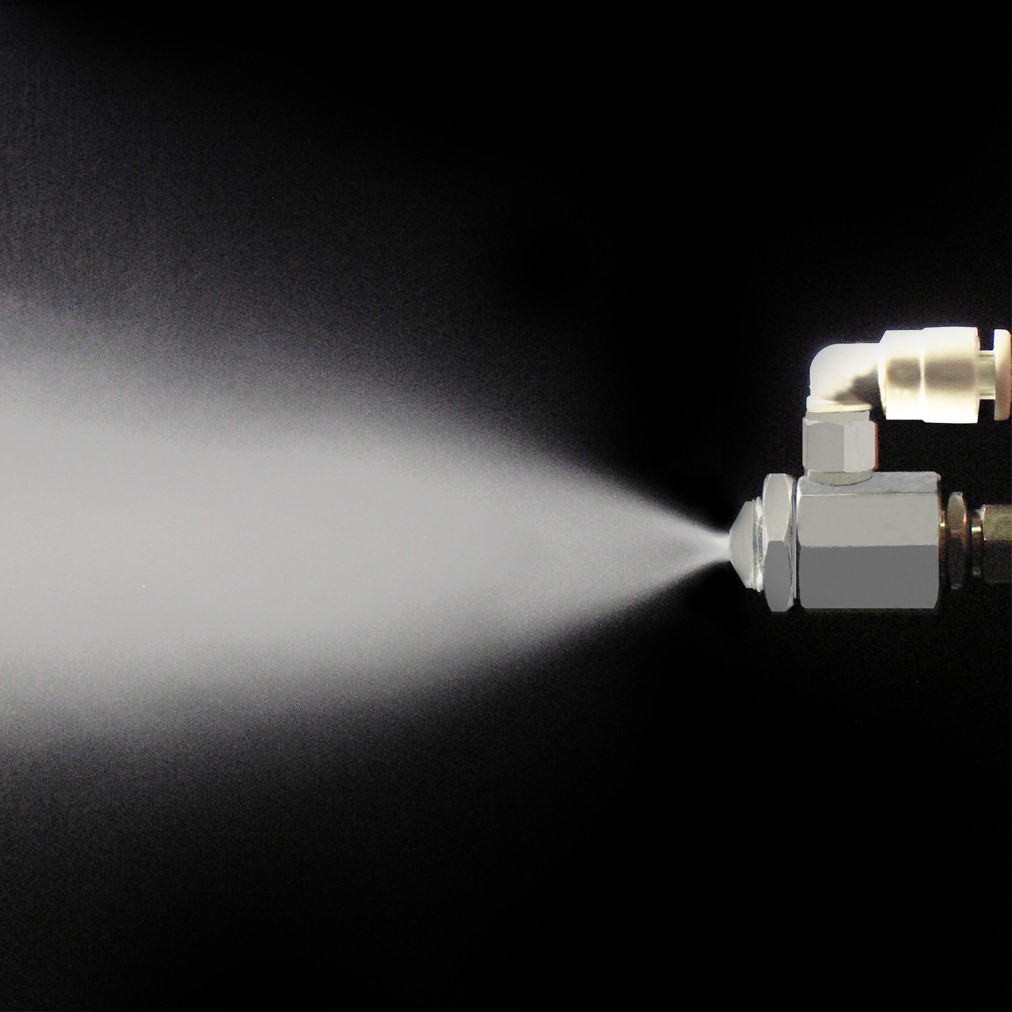

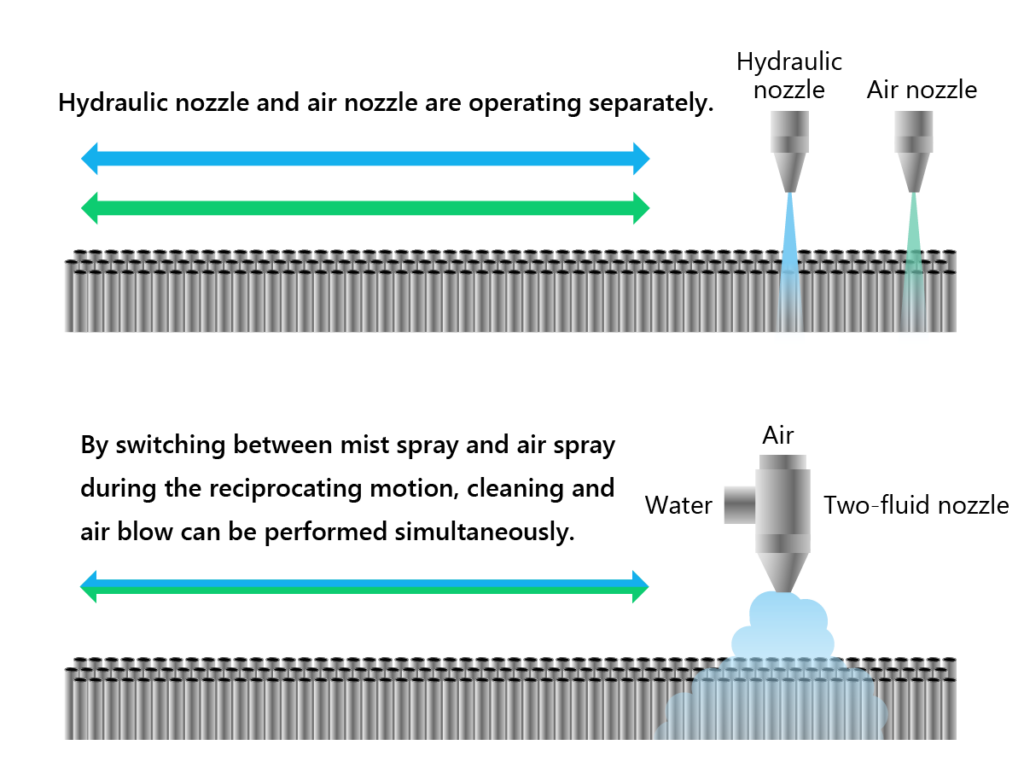

The cleaning process involved densely arranging the pipes, then sliding both a water-spray nozzle and an air-blow nozzle across the array to wash and remove residual particles.

Over time, the required quality standards became more stringent, and the existing automated system increasingly failed to meet the cleanliness criteria. To improve production efficiency and cleaning performance, the customer decided to reevaluate both the water-spray and air-blow nozzles and engaged our team for support.

Solution

We first proposed three nozzle options for the cleaning water spray:

1.Flat spray nozzle

Same flat spray pattern as the nozzle currently used in the equipment, but with a narrower spray angle to increase impact force and improve cleaning performance.

2.Straight jet nozzle

Switches to a straight spray pattern to increase impact force.

3.Air-water (two-fluid) nozzle, flat type

Changes to a two-fluid nozzle that mixes liquid and gas, generating a fine mist to enhance cleaning performance.

Trial

Based on testing the three proposed nozzle types with sample nozzles, it was found that the two-fluid nozzle, delivered the highest effectiveness. We then proposed additional two-fluid nozzles with different spray angles, from which is selected as the optimal nozzle.

Because the mist sprayed by a two-fluid nozzle consists of very fine droplets, it can penetrate holes and small gaps. With the assistance of air, the cleaning performance is considered to have improved.

A two-fluid nozzle atomizes by mixing water and air. If you stop the water during spraying, it will spray “air only,” allowing it to function as an air nozzle as well.

As a result, you decided on a method that uses a single nozzle traveling back and forth while switching between mist spray and air spray.

>For more information, explore “Basic knowledge and selection method of two-fluid nozzles”.