Challenges

Stamping is used in the manufacturing of products across a wide range of industries, with product sizes varying greatly. In particular, small components require a high degree of precision and complex shapes, making it difficult to form them in a single stage. As a result, it is common to use progressive stamping machines with multiple stages for such components. In the stamping process, it is essential to apply oil to the surface of the workpiece to suppress die wear and prevent galling on the workpiece. Oil application is a critical factor in maintaining quality during the stamping process, and there are various application methods.

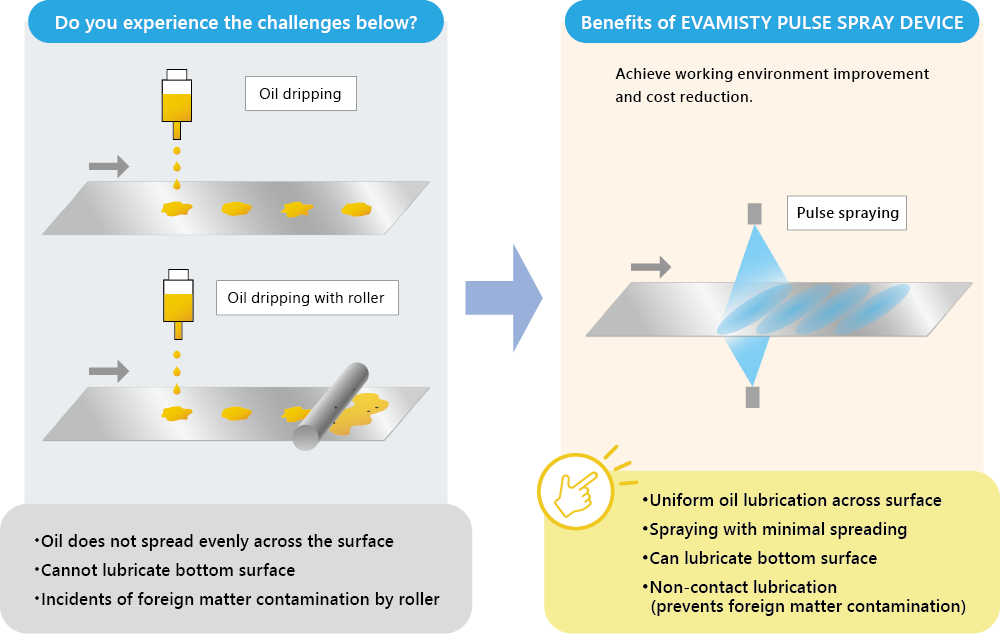

In this case, Our customer manufactures electrical connector components by stamping. Due to the low initial investment cost, they had adopted oil dripping with roller method. However, this method often failed to apply oil evenly to the workpiece, which negatively affected yield rates and the quality of the final products. In addition, the annual oil consumption was high, leading to increased costs. For these reasons, there was a demand to consider a new oil application method that could improve production efficiency and reduce total costs.

Solution

Generally, to minimize the amount of oil applied, spray method using a two-fluid nozzle is suitable. However, since this method emits a mist, which is a fine spray created by mixing air and oil, it can cause a deterioration of the work environment due to mist dispersion. As a countermeasure, it is effective to enclose the spraying area to prevent the mist from spreading outside the spray space. Therefore, we proposed the hydraulic pulse spray method, which enables minimal and uniform application with less mist dispersion.

The features of the hydraulic pulse spray method are as follows:

1) Compared with oil dripping and oil dripping with roller, it can coat both the top and bottom surfaces uniformly, without unevenness, and at a spray width suitable for the width of the workpiece. Being a non-contact process, there is also no risk of contamination.

2) In terms of oil consumption, compared with oil dripping and oil dripping with roller, this method can be expected to reduce production costs and decrease the occurrence of inadequate oil removal in subsequent processes.

3) Compared with the two-fluid spray method, mist dispersion is significantly reduced, which minimizes the impact on the work environment and human health, thereby improving safety.

Trial

In this case, after discussions regarding performance, pricing, and delivery time, we prepared a demonstration unit and conducted tests for a defined period at the actual production site. During the trial period, we confirmed the integration with the stamping machine, finely adjusted the oil spray amount by setting the valve-open time and frequency, and ultimately evaluated the quality of the finished products.