Challenges

This case study highlights our end-to-end support for a spray dryer manufacturer, from precision fabrication of the nozzle tip to performance testing.

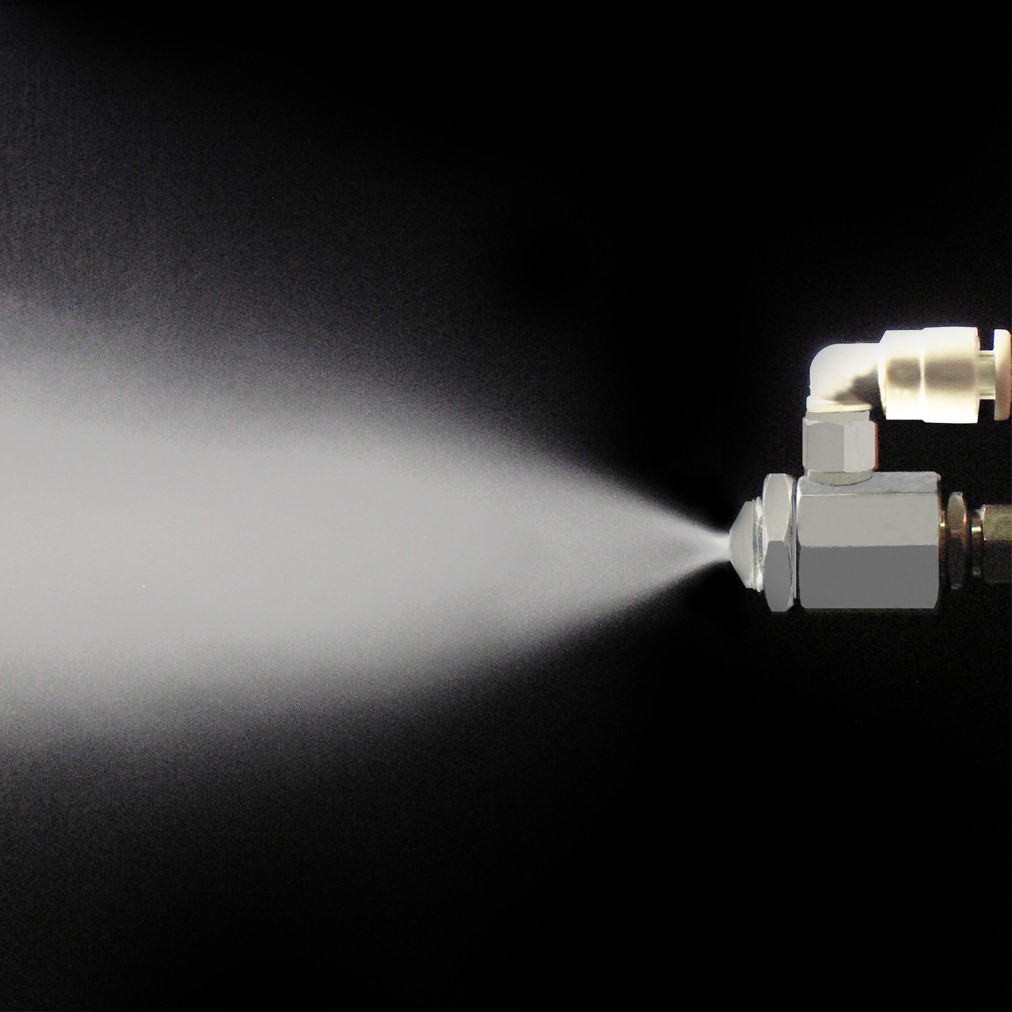

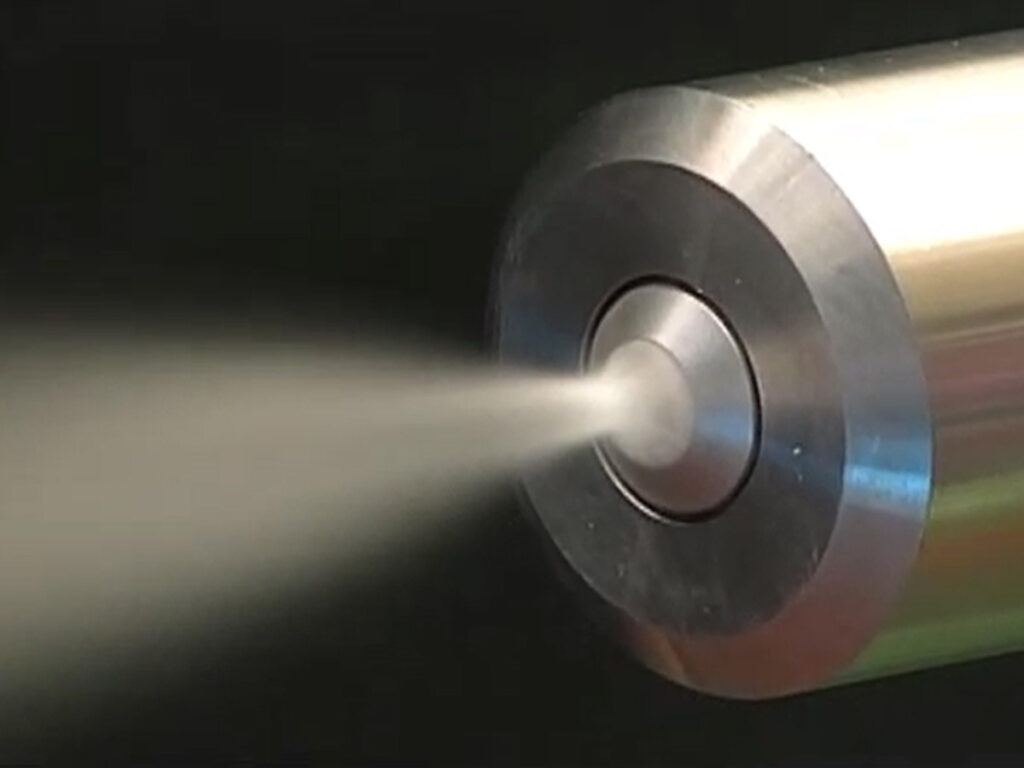

The customer designs and manufactures spray dryers but faced prolonged lead times due to involvement of multiple subcontractors in the production process. In particular, the nozzle tip—an element that critically influences spray dryer performance—requires not only high-precision fabrication and assembly, but also verification of atomization characteristics. As a result, the customer was seeking a manufacturer capable of handling the entire workflow, from fabrication through spray performance measurement and inspection, rather than a simple build-to-print arrangement.

Solution

The customer prioritized spray performance evaluation, with a particular focus on particle size measurement. However, particle size analyzers are highly specialized instruments owned by only a limited number of companies. We have possessed well-equipped testing facilities for spray nozzle design and development, establishing an extensive track record in performance assessment.

On the manufacturing side, spray dryers vary widely in size, presenting challenges due to the limited range of compatible machining equipment. To address this, we proposed an on-site visit to our production facility, where both measurement systems and machining capabilities are available. The customer’s design and engineering teams, along with production control representatives, visited the factory to review our equipment firsthand.

Trial

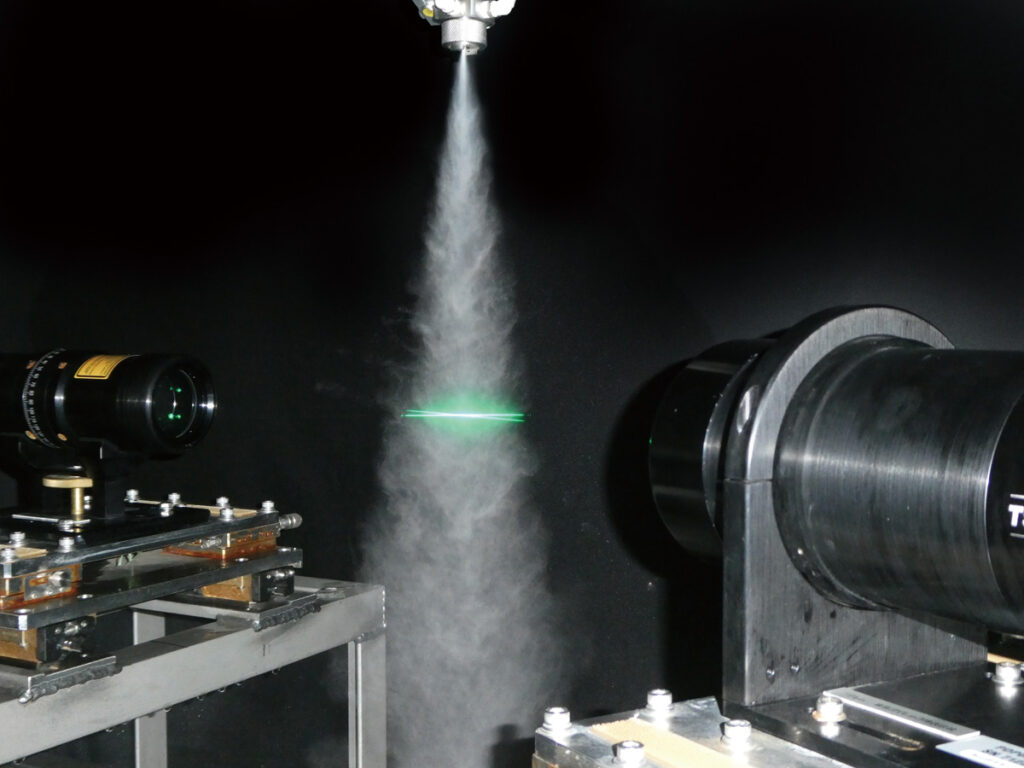

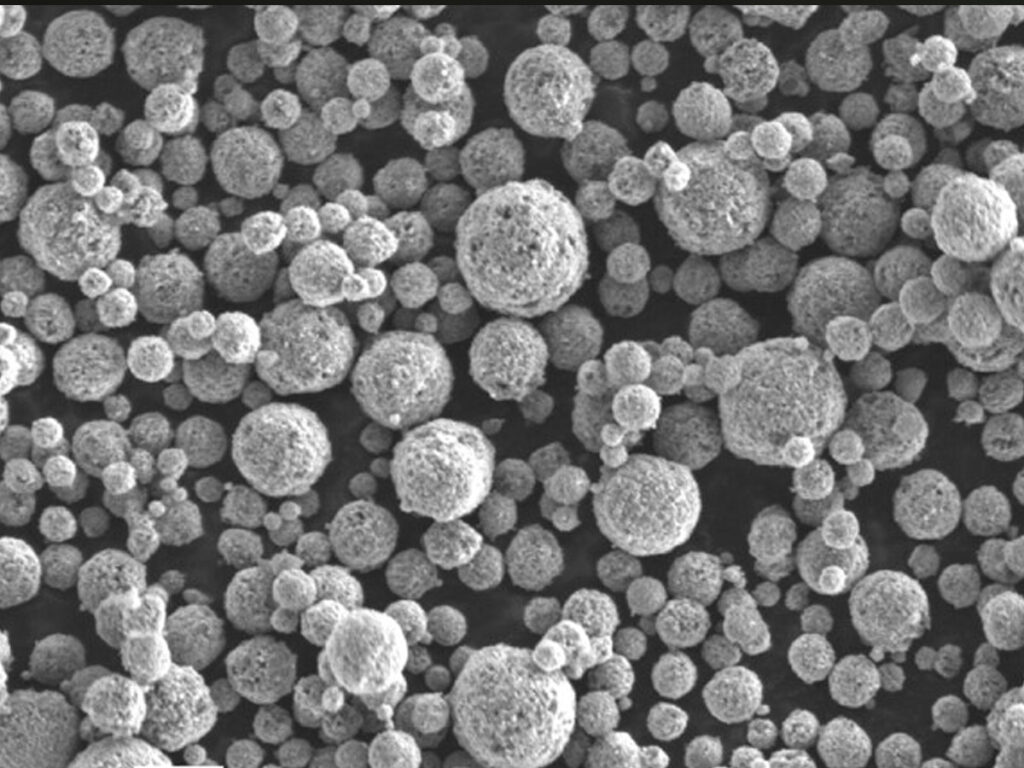

We maintain two types of particle size measurement systems. The first is an image-based particle size analyzer, used for higher flow rates and larger particle diameters. The second is a laser-based particle size analyzer, suitable for measuring relatively small particle sizes. Given that the spray in this project produced comparatively fine droplets, we employed the laser-based analyzer.

Because the nozzle’s geometry and spray direction differed from those typically used in standard tests, a custom setup was required. We carefully assessed potential impacts on measurement accuracy and, following detailed consultations with the customer, finalized an appropriate test methodology.

For more information, please see our Analysis & Evaluation.