Challenges

In the steel industry, continuous casting machines use mold cooling as primary cooling and spray nozzles for secondary cooling. During secondary cooling, the solidification of the slab occurs, so the uniformity of secondary cooling is a critical factor that significantly affects product quality.

If the cooling is insufficient or inappropriate, casting defects can occur within the product, leading to a decline in finished quality. Thus, it is essential to spray the cooling water evenly over the entire product in order to improve finished quality.

In this case, our customer was concerned about the risk of quality deterioration due to uneven water spray in their existing secondary cooling system. They sought to build a new secondary cooling system that could achieve more uniform water spray and further enhance the quality of steel.

Solution

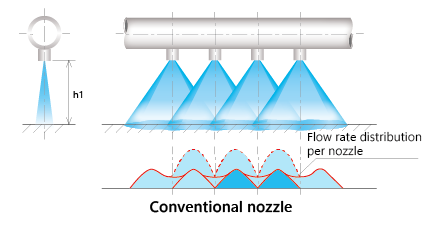

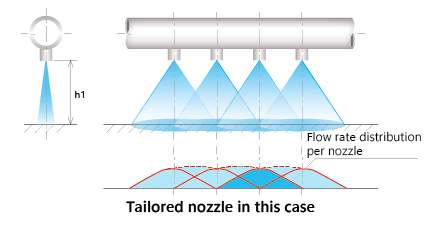

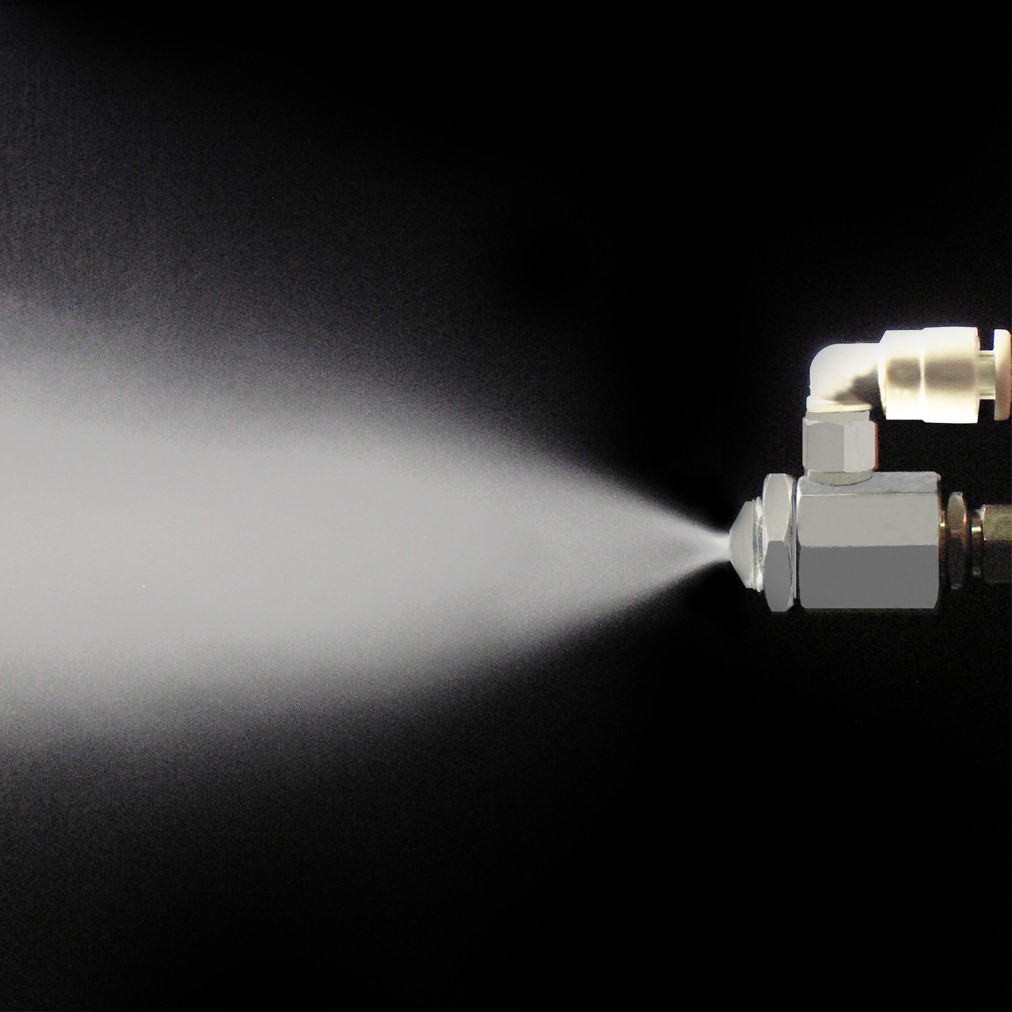

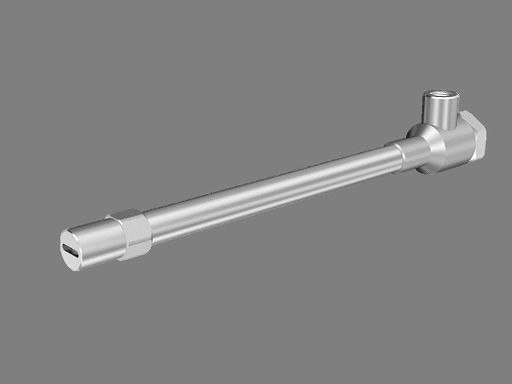

We proposed the use of tailored air mist spray nozzles instead of standard spray nozzles to achieve uniform cooling. With standard spray nozzles, it is difficult to ensure uniform water distribution over the slab width. Therefore, designing and manufacturing optimal spray nozzles specifically for the targeted slabs leads to more uniform cooling.

When using standard spray nozzles, the flow rate distribution tends to be uneven. For this reason, the key aspects of customization are the spray angle and flow rate distribution.

Trial

First, we collected the conventional nozzles from the customer and conducted flow rate distribution measurements and Heat Transfer Coefficient(HTC) measurement system at our facility. By identifying the causes of non-uniformity with the conventional nozzles, we began designing customized nozzles, focusing on spray angle and flow rate distribution. After finalizing the nozzle design, we repeatedly manufactured prototypes and performed flow rate distribution measurements and Heat Transfer Coefficient(HTC) measurement multiple times. Through this iterative process, we successfully developed tailored air mist nozzles capable of achieving uniform flow rate distribution.