Challenges

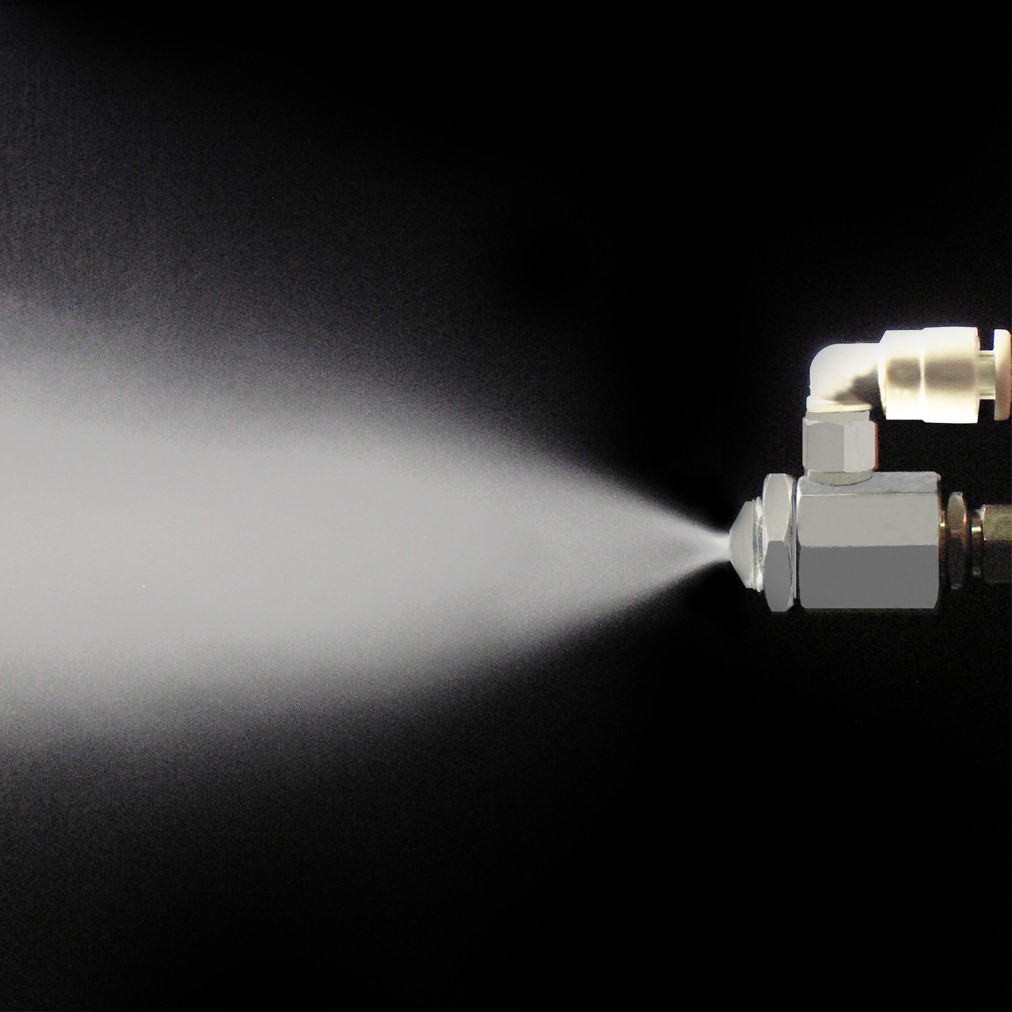

In the steel industry, continuous casting machines use mold cooling as primary cooling and spray nozzles for secondary cooling. During secondary cooling, the solidification of the slab occurs, so the uniformity of secondary cooling is a critical factor that significantly affects product quality.

If the cooling is insufficient or inappropriate, casting defects can occur within the product, leading to a decline in finished quality. Thus, it is essential to spray the cooling water evenly over the entire product in order to improve finished quality.

However, since the cooling water is recirculated and reused, it often contains foreign matter. When such foreign matter enters the spray nozzles, it can cause clogging. If the nozzles become clogged and cannot spray, adequate cooling cannot be achieved, which may result in defects such as cracks or deformation in the slab, and may also damage production facility. Machinery breakdown can severely impact production efficiency and product quality, so preventive maintenance is necessary. However, since these machines operate continuously, nozzle maintenance cannot be performed frequently. For this reason, our customers requested nozzles that are resistant to clogging while maintaining the required performance, in order to minimize the risk of defective products and avoid damage to production facility.

Solution

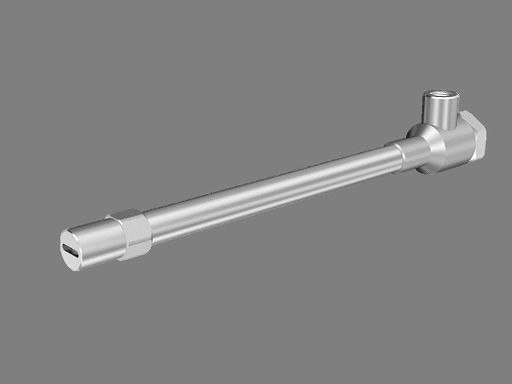

We proposed the introduction of customized spray nozzles based on our standard spray nozzles. Since the flow paths of the nozzles were narrow and clogging due to foreign substances was occurring, we believed that manufacturing spray nozzles with enlarged minimum flow paths would help prevent clogging caused by such substances.

The challenge was that enlarging the minimum flow path could result in performance differences between the customized spray nozzles and the conventional ones.

Trial

First, we received the existing nozzles from the customer and measured the flow rate distribution at our in-house flow rate distribution measurement system to assess the performance of the spray nozzles. Next, we discussed the minimum flow path based on the customer's facility conditions and designed a customized nozzle to enlarge the minimum flow path while maintaining performance.

We then produced prototypes and measured the flow rate distribution of the customized nozzles with enlarged minimum flow paths. We repeated the process of making adjustments to the prototypes and conducting tests until we achieved spray performance equivalent to the existing nozzles. As a result, we were able to manufacture a spray nozzle with improved resistance to clogging that met the customer’s requirements.