Challenges

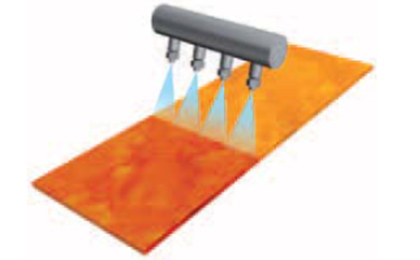

In hot strip mills and plate mills, descaling nozzles are utilized to remove scale from the steel surface. If scale is not properly removed, the scale, which is harder than the steel itself, can bite into the rolled coils, causing surface defects known as scale marks on the steel plate and resulting in quality issues.

In recent years, the steel grades—such as automotive high-tensile steel sheet and electrical steel sheet—have increased, and there have been cases where conventional descaling nozzles have not sufficiently removed the scale. While increasing nozzle flow rate or pressure can improve scale removal efficiency, implementing such measures requires equipment upgrades, which can be challenging and costly. Therefore, there was a significant demand for spray nozzles that could improve scale removal performance without requiring upgrades to existing utilities.

Solution

We recommended replacing the legacy descaling nozzles with our newly developed, high impact force descaling nozzle. This new design achieves significantly higher impact force, enabling more effective scale removal while reducing water consumption by 10–20% compared with the conventional nozzles.

Trial

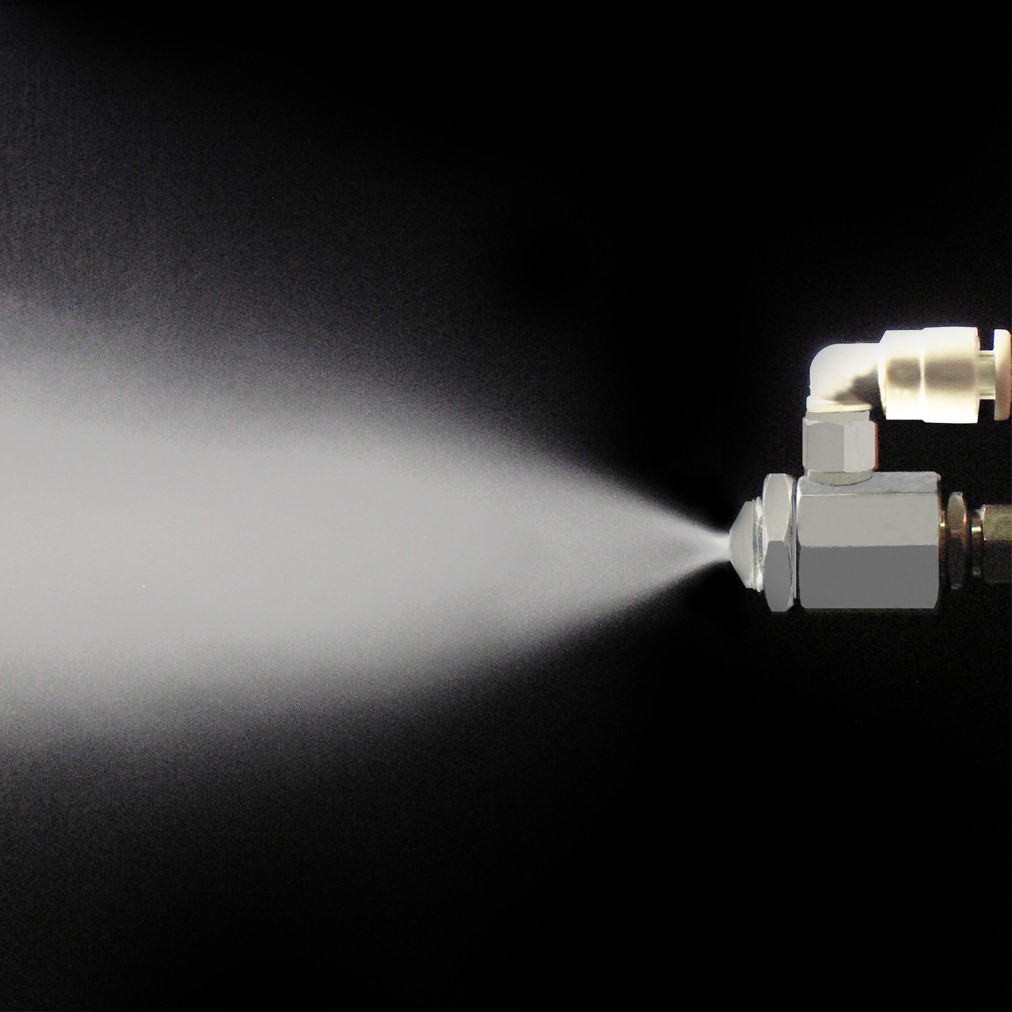

We conducted head-to-head tests of the conventional nozzle versus our new high-impact design.

First, we conducted impact force distribution measurements using the conventional descaling nozzle and new descaling nozzle. Using our in-house impact-force measurement, we compared both the maximum impact force and the distribution of impact force in the width direction.

Impressed by the significant improvement in maximum impact force shown in our test result, the customer highly evaluated the new descaling nozzle and decided to implement it.