Challenges

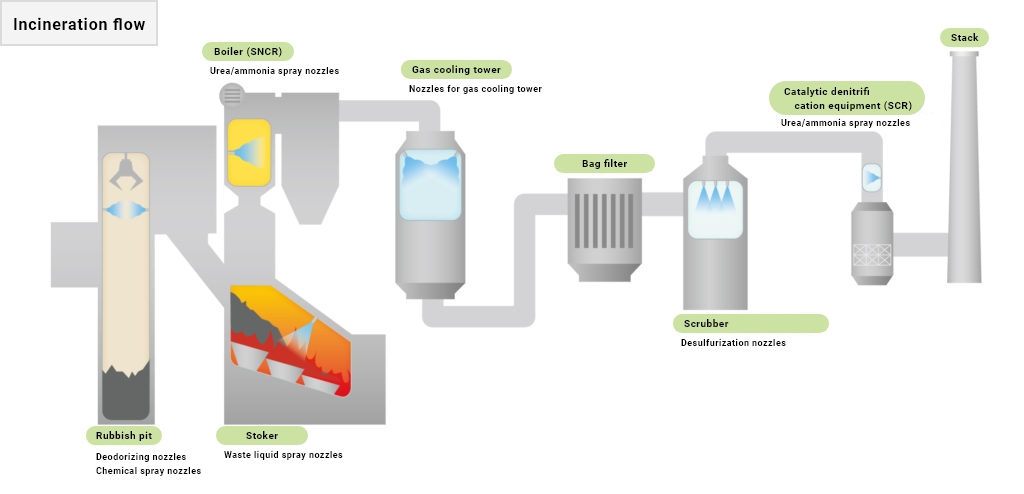

Some exhaust gas is generated since massive amounts of garbage are burnt at garbage incineration facilities. The exhaust gas contains harmful substances such as sulfur oxide(Sox), nitrogen oxide(NOx), dioxin and others, which have to be properly treated. In general, a filtration type dust collector called bug filter is used. To let the exhaust gas flow through the bag filter, the gas temperature has to decrease down to less than 200 degrees Celsius to avoid activate the harmful substance such as dioxin. For this, cooling down is completed by spray nozzle's mist spray.

Gas cooling plays an important role in processing some harmful substances. If the exhaust gas didn't cool down efficiently, the harmful substances would be activated, which would deteriorate the exhaust gas process. Although a regular maintenance is frequently scheduled, the maintenance, any inspections can't be often performed due the massive garbage incinerator .

In this case, one of our customers was looing for a spray nozzle with clogging improvement since the current spray nozzle led to some clogging issues even with some scheduled maintenances.

Solution

We proposed a spray nozzle with the enlarged orifice to avoid some clogging, keeping the required flow rate and spray angel for the gas cooling performance. However, switching to a whole complete set of spray nozzle would cost more and take more time, we proposed switching only the nozzle tip part. We designed the customized nozzle tip prototype only for the nozzle tip change, which enabled the customer to meet the customer's request with such a huge cost deduction.