Challenges

Painting equipment is used in applying some paints. There are several different painting equipment such as a manual type with hand spray, an automated type with a painting robot or others. In any painting equipment, spray nozzles are generally used in any painting equipment.

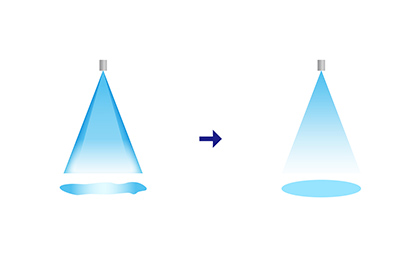

There is one issue in the painting equipment with spray nozzles, which is tailing. Tailing is the condition that a thick spray line appears in each side of spray pattern when sprayed. That would deteriorate painting qualities and aesthetic sense. Since various kind of paining is available recently, especially when high viscosity paint is sprayed, spraying with an inappropriate nozzle cause tailing at a higher possibility.

In this case, one of our customers was looking for an alternative spray nozzle with an uniform paint spray distribution since they had some tailing issues in applying some solvent-reflective coating with the other spray nozzle manufacturer's standard spray nozzle. As mentioned above, tailing deteriorates painting qualities and aesthetic sense. The current nozzle manufacturer was not able to propose what the customer was satisfied with even though they requested the manufacturer to fix the issue. Because of that, the customer contacted us.

Solution

After evaluating the other nozzle manufacturer's standard nozzle, we compared it with our standard ones. However, the test results showed not only the same flow distributions but also a tailing occurrence on a painting equipment. Due to the consequences, we proposed a special nozzle with customized flow distribution to block the tailing issue.

Trial

We found out the factor that a non-uniform spray patter by measuring the flow distribution of the competitor's nozzle installed currently. In addition to this, not only the competitor's nozzle, we evaluated our several standard nozzle's flow distributions to customize the special nozzle flow distribution. After making a prototype, we kept testing the flow distribution and modifying the prototype. After these repeated processes, the orifice type customized nozzle was designed with the uniform spray pattern.