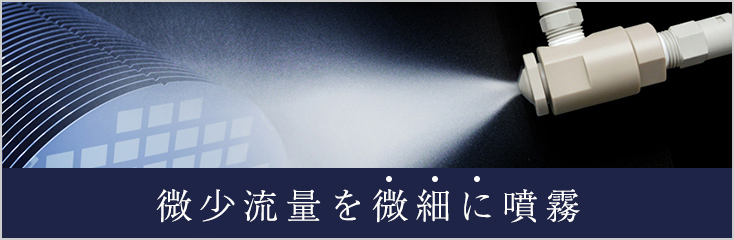

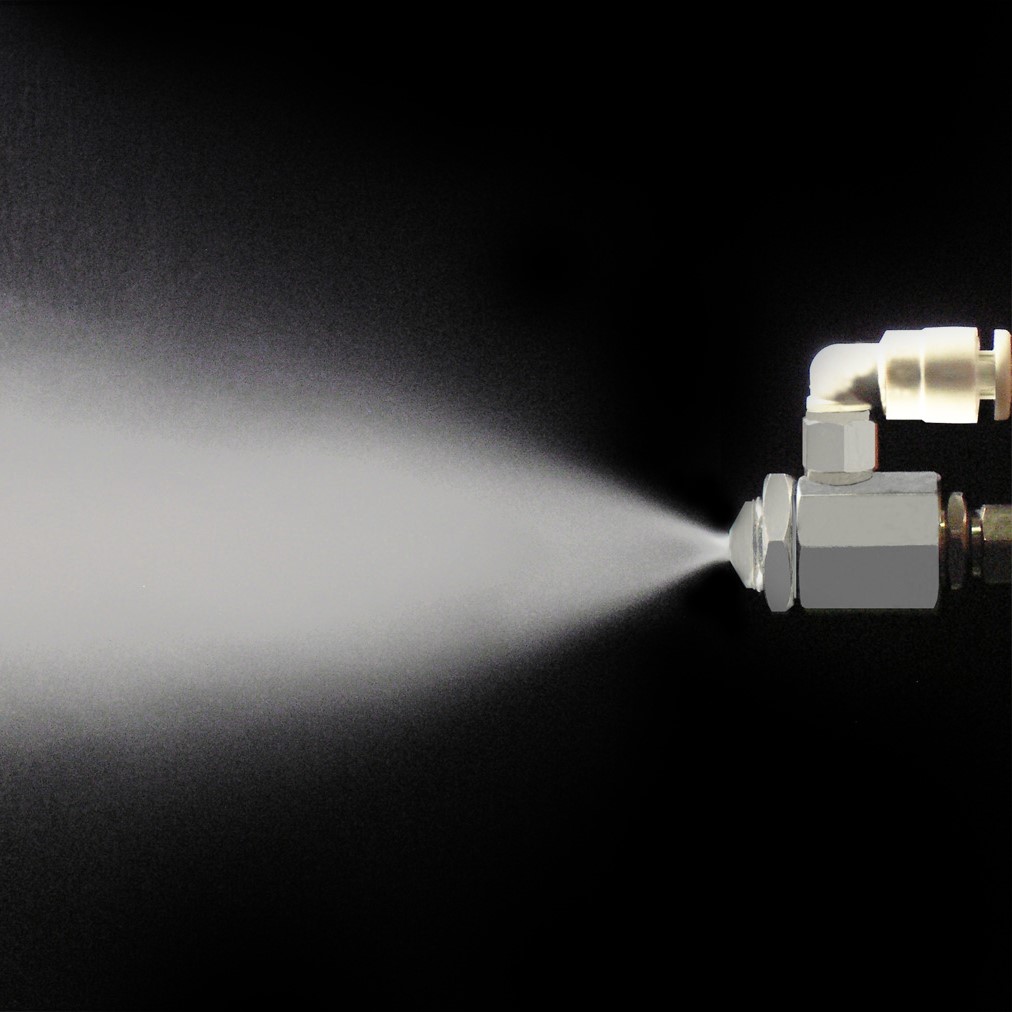

スプレーノズル ・エアーノズル

ソリューションナビが選ばれる理由

スプレーノズル・エアーノズル ソリューションナビは、

ノズルの設計開発技術と評価技術によって様々な業界のお客様に選ばれ続けてきました。

私たちが選ばれ続ける理由を掲載しています。

-

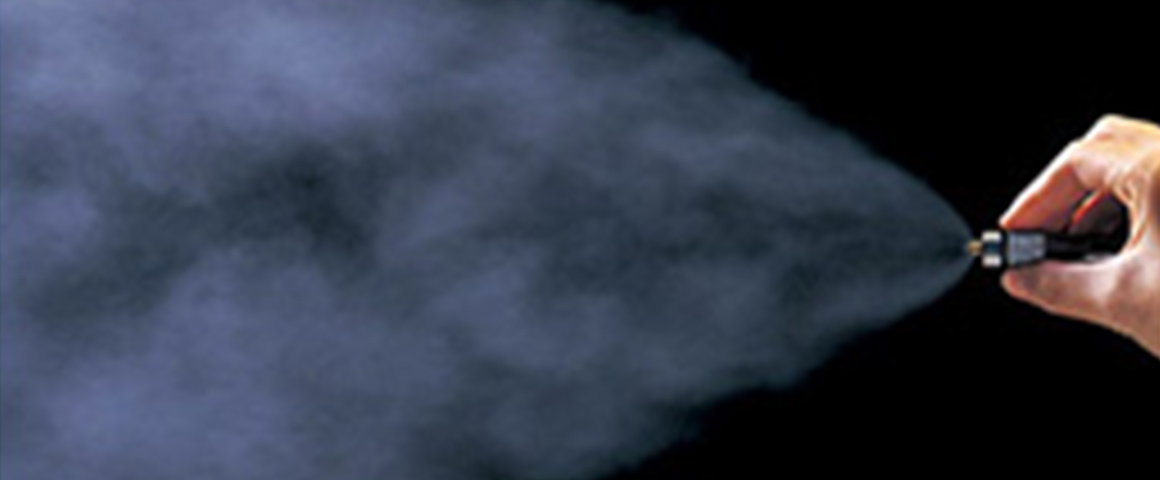

ご要望に合わせた

カスタム対応設計開発技術と解析・評価技術により、皆さまのニーズに合致した特注ノズルをご提供します。

-

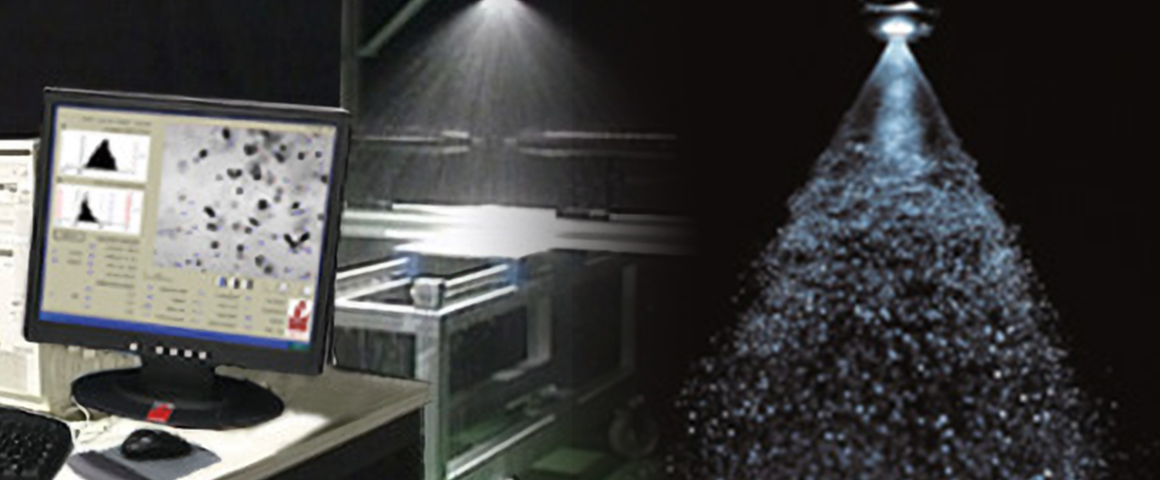

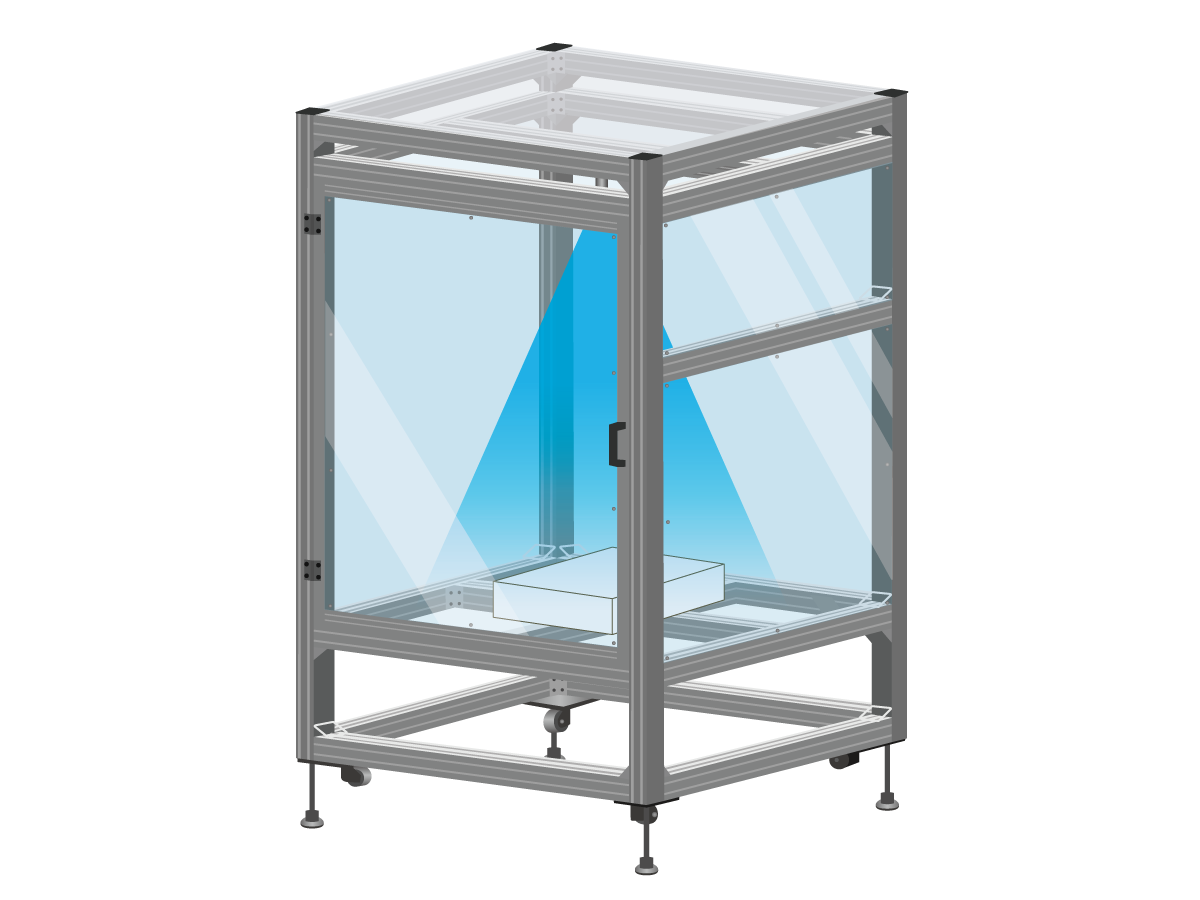

最適化提案を可能にする

解析・評価技術充実した評価試験設備と解析技術により、問題点を洗い出し、最適化したノズルをご提供します。

-

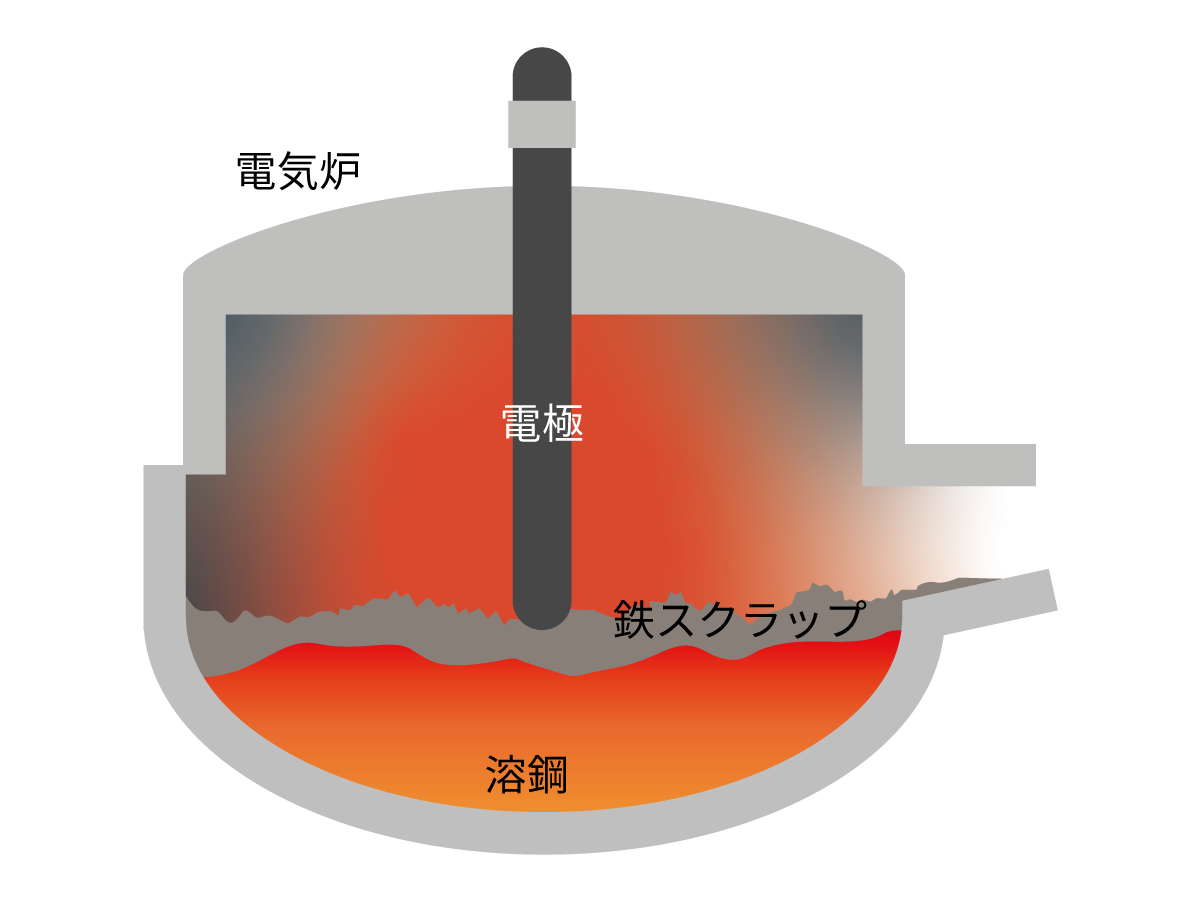

超硬合金を使用した

高付加価値ノズルの製作超硬合金メーカーでもある当社のノウハウを用いて、長寿命化など、高付加価値なノズルをご提供します。

-

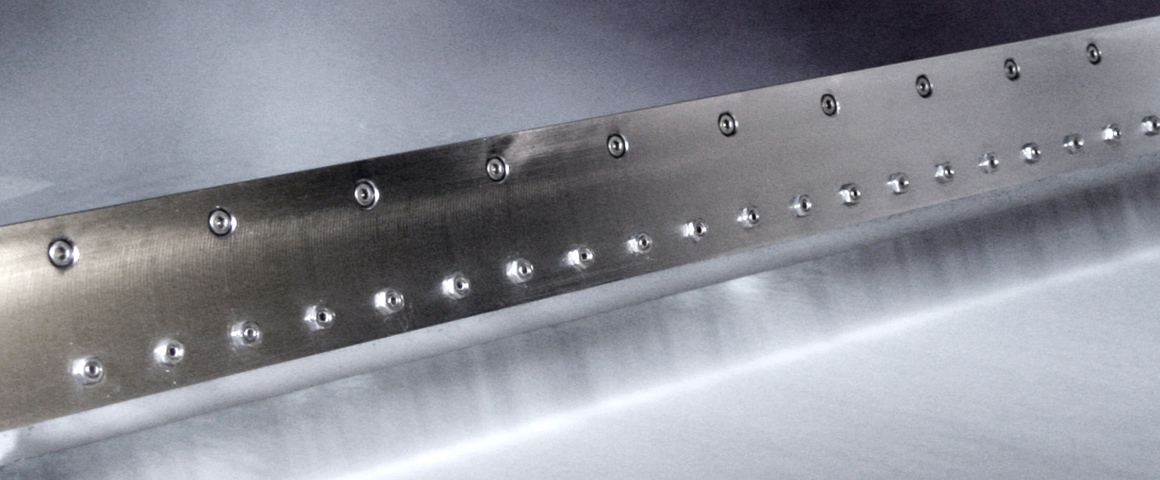

多種多様なノズルの

フルラインナップ標準スプレーノズル・エアーノズルをフルラインナップ取り揃えることで、最適なノズルをご提供します。

-

多岐にわたる業界への

年間60万個のノズル様々な業界へのノズル納品実績を持ち、各業界の専門知識・ノウハウにより最適なノズルをご提供します。

サービス

ノズルに関するお困りごと・課題をお持ちの方へ。

皆さまの困難な課題を解決します

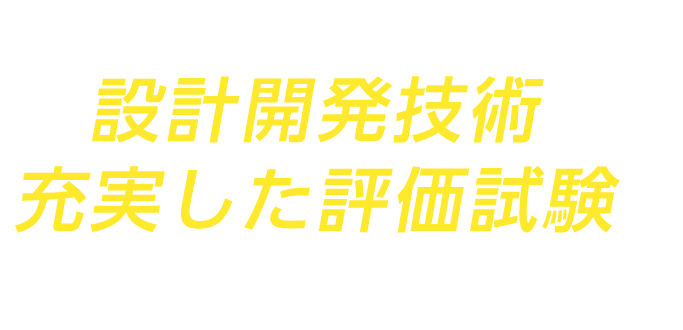

設計開発事例を探す

スプレーノズル・エアーノズル ソリューションナビを運営するエバーロイが、

過去にお客様に提供した特殊ノズルの設計開発事例を掲載しております。